How Our Auger Blades and Points Slash Maintenance Costs and Reduce Downtime

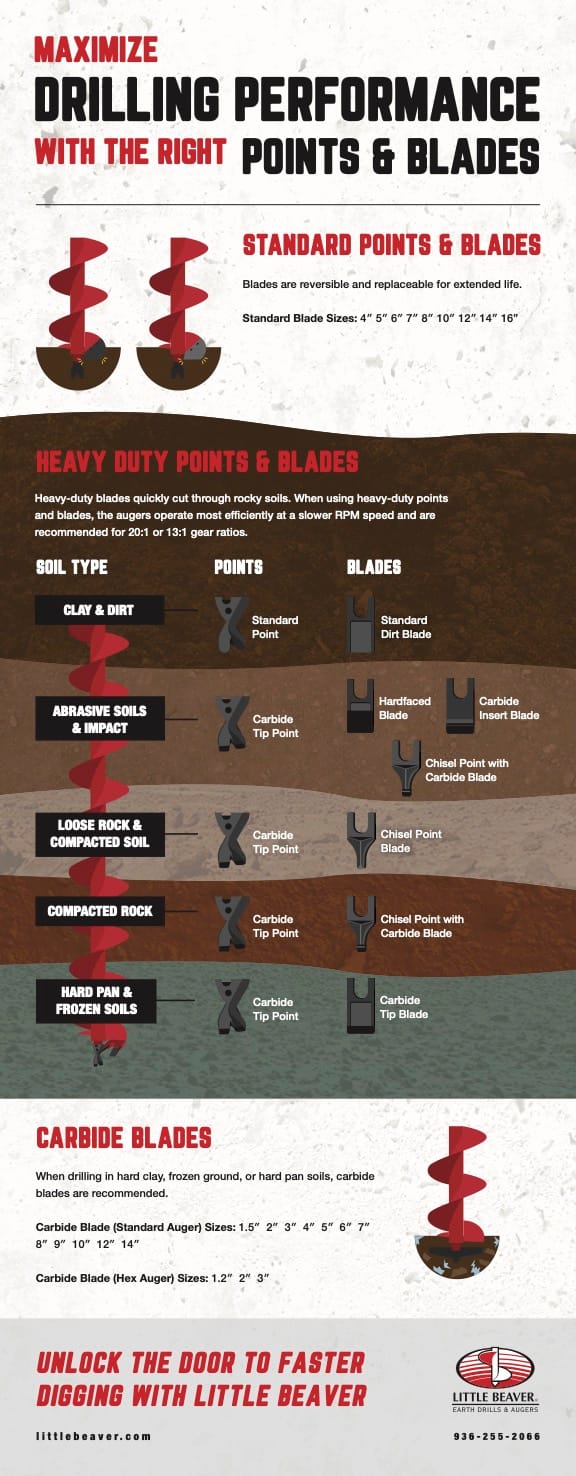

High-maintenance machines can be a real headache when you want to maximize uptime. That’s why it’s important to have the right equipment well-suited for whatever task and sediment you’re working with. Matching the ideal point and blade to the specific soil type minimizes premature wear, maintenance costs and labor. Unlike manufacturers that only make one auger blade, Little Beaver produces a variety of augers, points and blades. The components are designed for optimizing your ability to cut through a variety of soil profiles.

Our replaceable blades and points mount on our regular and heavy-duty snap-on augers with ease. They protect the earth augers from wear while drilling in material that ranges from loamy soil to compacted rock. Since drilling a bunch of holes in the ground can be time consuming, here are a few ways we make it easier.

Little Beaver manufactures a variety of augers, points, and blades designed to optimize their ability to cut through specific soil profiles.

Ease of Use, Low Maintenance

“We want to keep our customers drilling without interruption,” said Little Beaver President Joe Haynes. “We designed our blades and points for simple replacement on our signature snap-on augers so operators can focus on digging and quickly change out parts when they become dull or worn.”

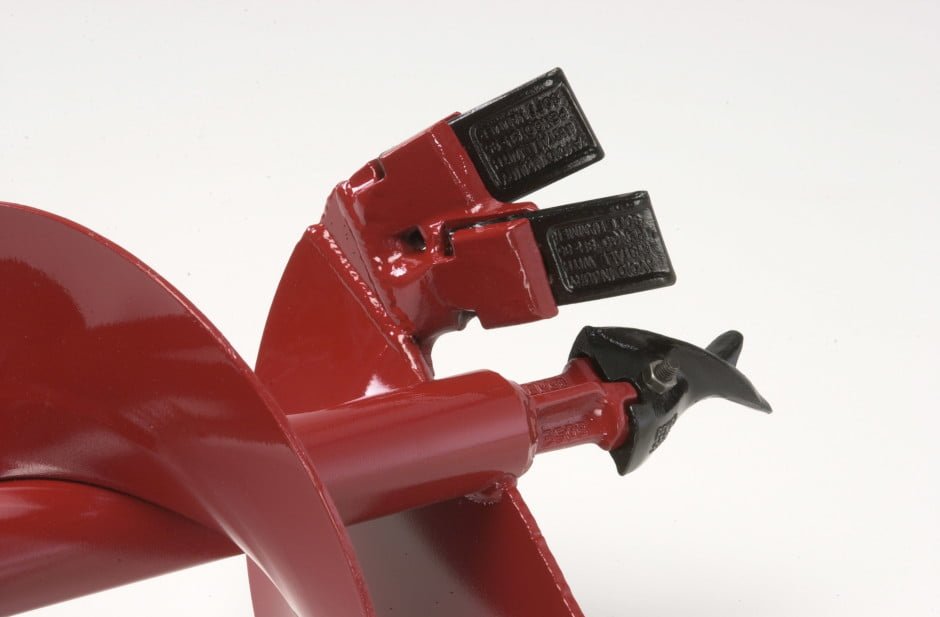

The standard blades and points come with every Little Beaver snap-on auger. They fasten to the auger with two steel bolts, which operators can easily remove with a crescent wrench. Made with abrasive-resistant steel and hard surfacing on their edges, these components are ideally suited for loamy soils with few rocks.

Equipped with Little Beaver blades and points, an auger can drill more than 100 holes in prime soil conditions before you need to service it. Our parts are easy to use and require low levels of maintenance — benefits that remain unmatched across the industry.

Rugged and Versatile

Smaller-diameter augers — 1-1/2-inch, 2-inch and 3-inch — use standard points that simply screw or pin on. For dense soils, we offer Little Beaver exclusive carbide blades that fasten to the bottom of snap-on augers. They cut hard clay and frozen ground into smaller pieces.

“Many operators keep both the standard and carbide blades on hand if they will be transitioning between multiple jobsites. It’s quick and easy to make the swap,” Haynes said. “Having both sets enables digging in a diversity of soil conditions. It also prolongs the lifespan of blades and augers.”

To take on the most challenging soil formations, Little Beaver’s lineup of heavy-duty snap-on augers use specially engineered, heavy-duty steel and carbide blades and tips for abrasive soils and compacted rock. They lock into larger-diameter augers with rubber locks, forming a tight wedge fit to cut through tough sediment without coming loose.

Let’s Make It Happen

Little Beaver’s commitment to innovation and versatility for customers makes its augers, blades and points a reliable choice for professionals in the field, enhancing drilling efficiency while reducing overall operational costs. We would love to collaborate on maximizing the value of your earth drilling operation. To learn more, give us a call at 936-327-3121 or fill out our online contact form and a member of our team will be in touch with you soon.